Avoiding stainless steel casting lowers energy use and pollution.

Opting for stainless steel over past leaded brass and zinc alloys in water hardware prevents heavy metal release, cuts out chromium electroplating, and reduces expenses and pollution.

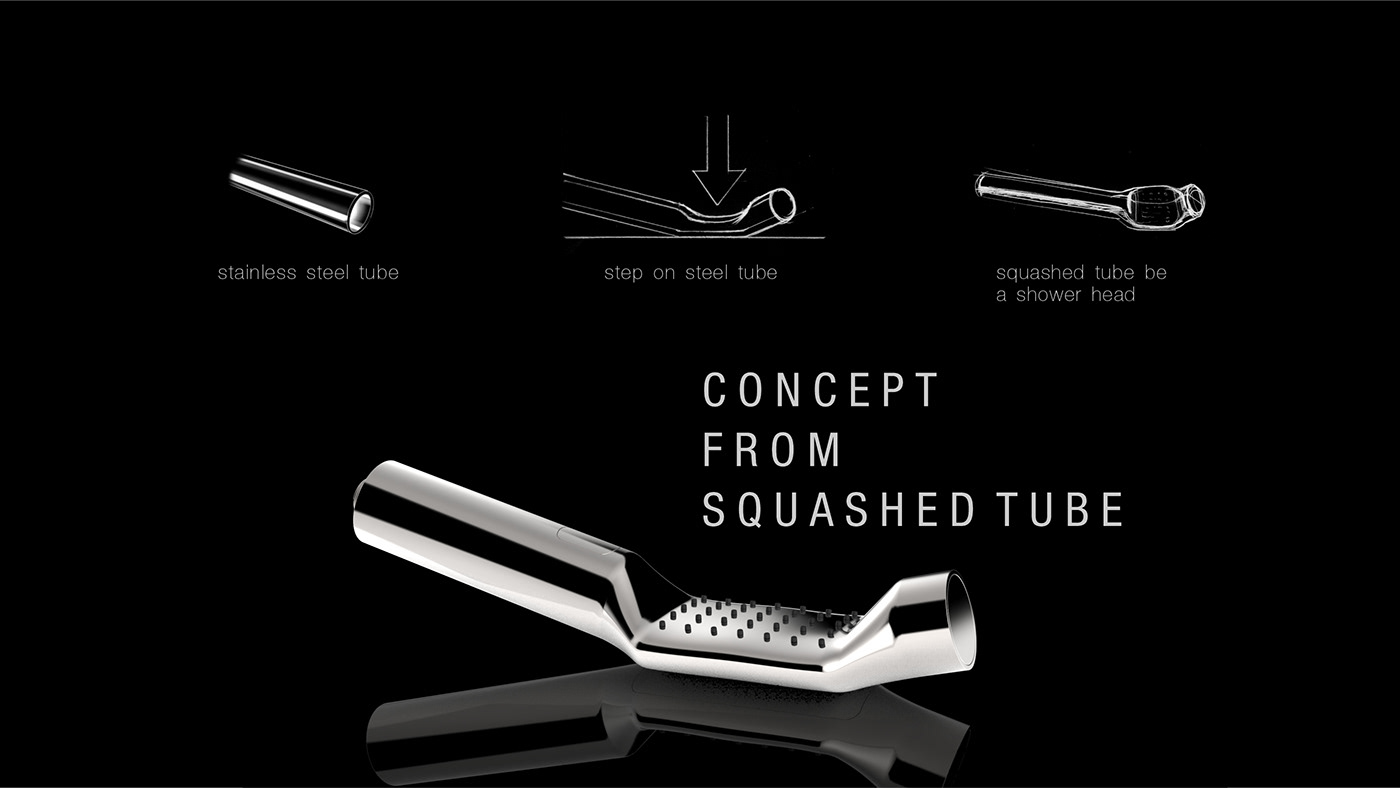

Hydroforming replaces casting and minimizes labor in grinding and polishing.

Stainless steel casting, a highly polluting, high-energy industry, is transitioning to eco-friendly processes via hydroforming.

Stainless steel finishing relies heavily on labor. This design avoids sand casting, notably cutting surface polishing costs. Hydroforming starts with bright stainless steel tubing, saving labor in later grinding.

Aligns with eco trends.

Environmentally friendly PVD titanium plating for stainless steel coloring obviates traditional chemical electroplating.